PICTURE FRAMING SUPPLIES

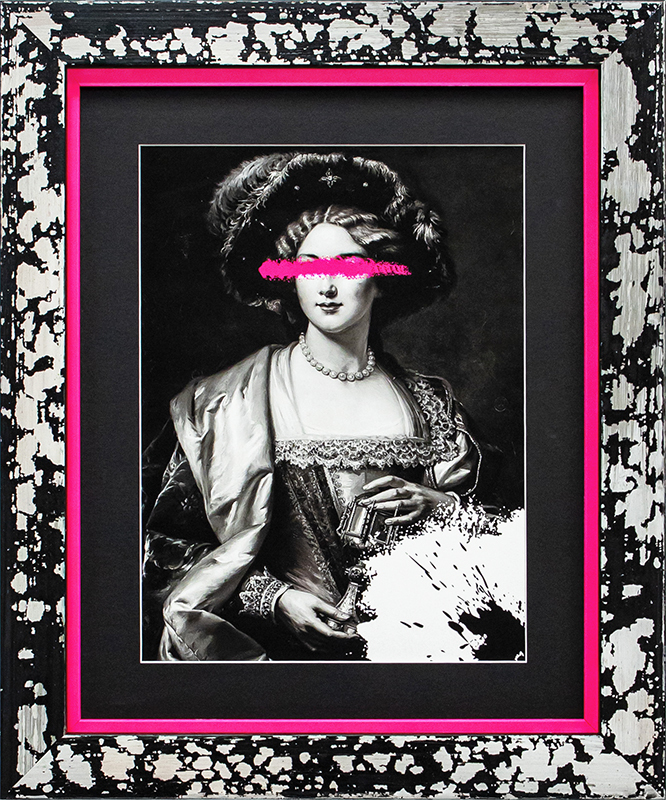

We are passionate about mouldings and our search for innovative and distictive new ranges is an ongoing commitment. From contemporary to traditional, ornate to understated, informal to chic, we source high-quality, sustainable, value for money products which not only fulfil everyday needs but stimulate creativity, excite and inspire.

As a wholesale provider, we take great pride in delivering a dependable, efficient and friendly service to all our customers from the Hobbyist to the Factory Framing Business. Mouldings can be purchased by the box, pack and individual length to suit all size of orders. Our 'supersearch' allows our entire catalogue to be searched - filtered by size, colour, profile and finish - to find the perfect moulding for your customer quickly and efficiently.

For busy managers who know what they need and want to order quickly, take a look at the 'Speedy Shop' where you can build an order, upload a spreadsheet or start from a previous order.

Build an order (speedy shop)

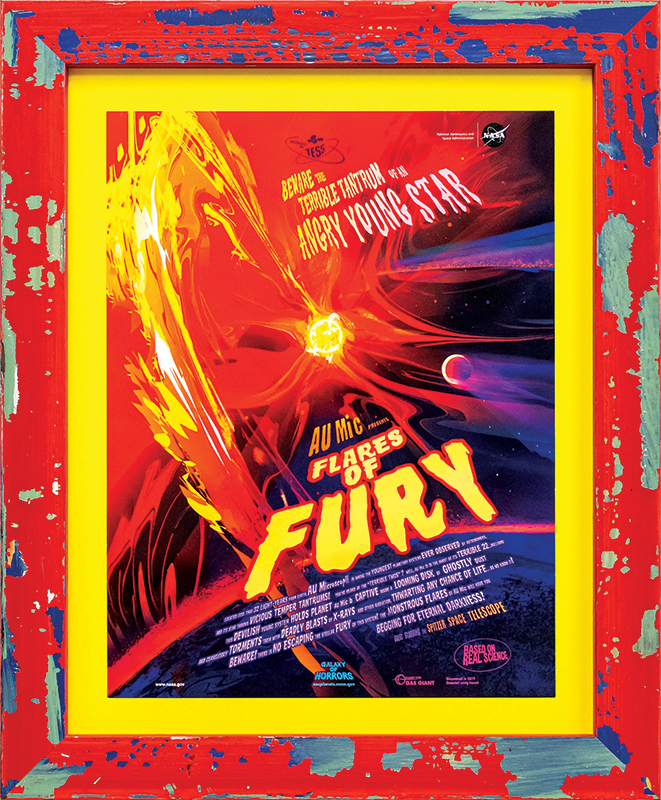

WOOD

Our vast array of keenly priced wood picture frame mouldings will enhance all styles of art and photography, match to any colour scheme and complement any décor trend. View all wood frame mouldings.

Polcore®

Mainline’s own brand of design-led extruded frame moulding made from over 80% recycled polystyrene. Available in over 1,000 designs and profiles, and unbeatable value for money! View all polcore® frame mouldings.

Download Our Brochures And Information Sheets

Beautiful brochures and detailed bits of information.